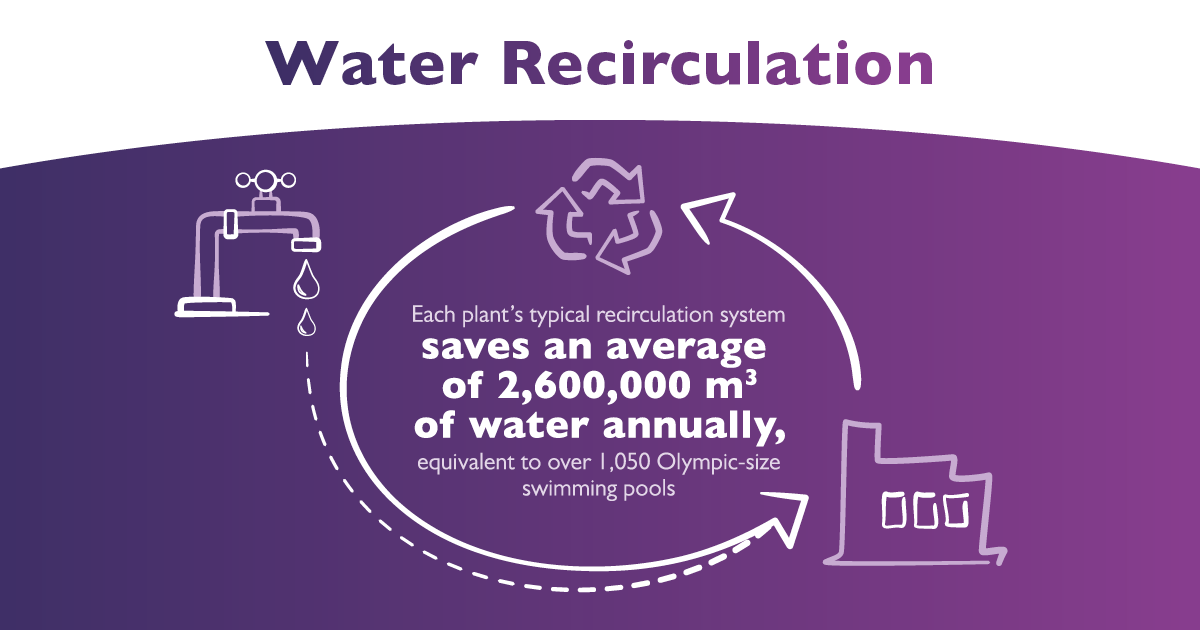

Water is a vital resource and reducing water consumption by 25% by 2030 is one of our 10 corporate sustainability goals in line with the SDGs. Before now, water supply was not historically a challenge in northern Italy, but due to climate change, regions there have faced long periods of drought. Our plant in San Polo, Italy, recently completed two projects to reduce water use.

Water Reduction at O-I’s San Polo Plant

Glass plants use water during the cooling portion of the manufacturing process.

The San Polo plant in northern Italy examined its water use and found areas of opportunity. One project created a closed-loop water system. Water used to cool the furnace bubblers is now recirculated into the cooling system for the furnace’s dust filter.

Creating a closed-loop water system reduces the amount of new water the plant needs to make glass. The improvements also enable the plant to continue producing glass through future drought periods, sustaining it through potential water supply rations that would have otherwise limited supply.

Teams also installed modern new sinks in the hot zone. The new sinks feature a pedal system that allows workers in the hot end to better control how much water they need for hydration — as well as washing their hands.

Together, the two water-saving projects save an estimated 60 mc/day; the annual water savings is equivalent to the water needed to fill an Olympic-sized swimming pool more than eight times.

O-I’s Commitment to Responsible Water Management

O-I is focused on being good stewards of the water we use in the glass-making process. We launched a Water Reduction Roadmap in 2022 to chart our journey. We’re also focused on improving our monitoring systems and standardizing our data collection globally.

Read more about our commitment to sustainable glass manufacturing in our sustainability report.