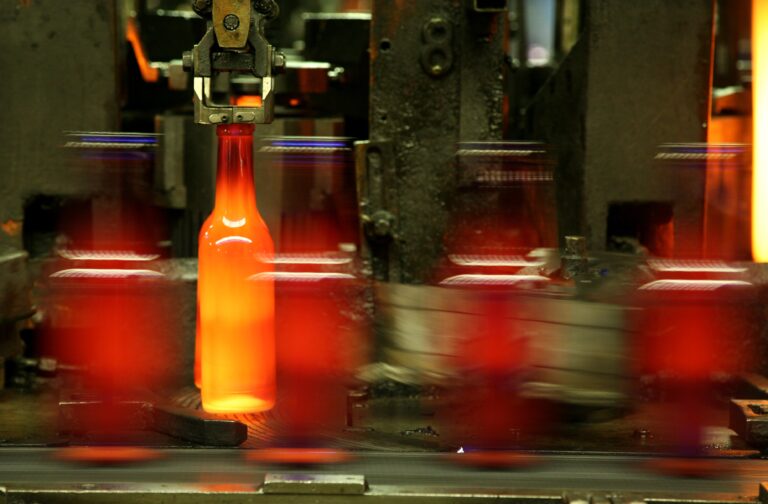

O-I is opening a new recycling hub for cullet suppliers in Barranquilla, Colombia. A cullet hub is a material collection center where we buy cullet from suppliers in the local area, in this case, the Atlantic Coast, which is more than 550 miles from O-I’s plant. The opening of the facility, located on Colombia’s northern coast, is part of our strategic plan to keep more glass in the manufacturing stream and out of landfills.

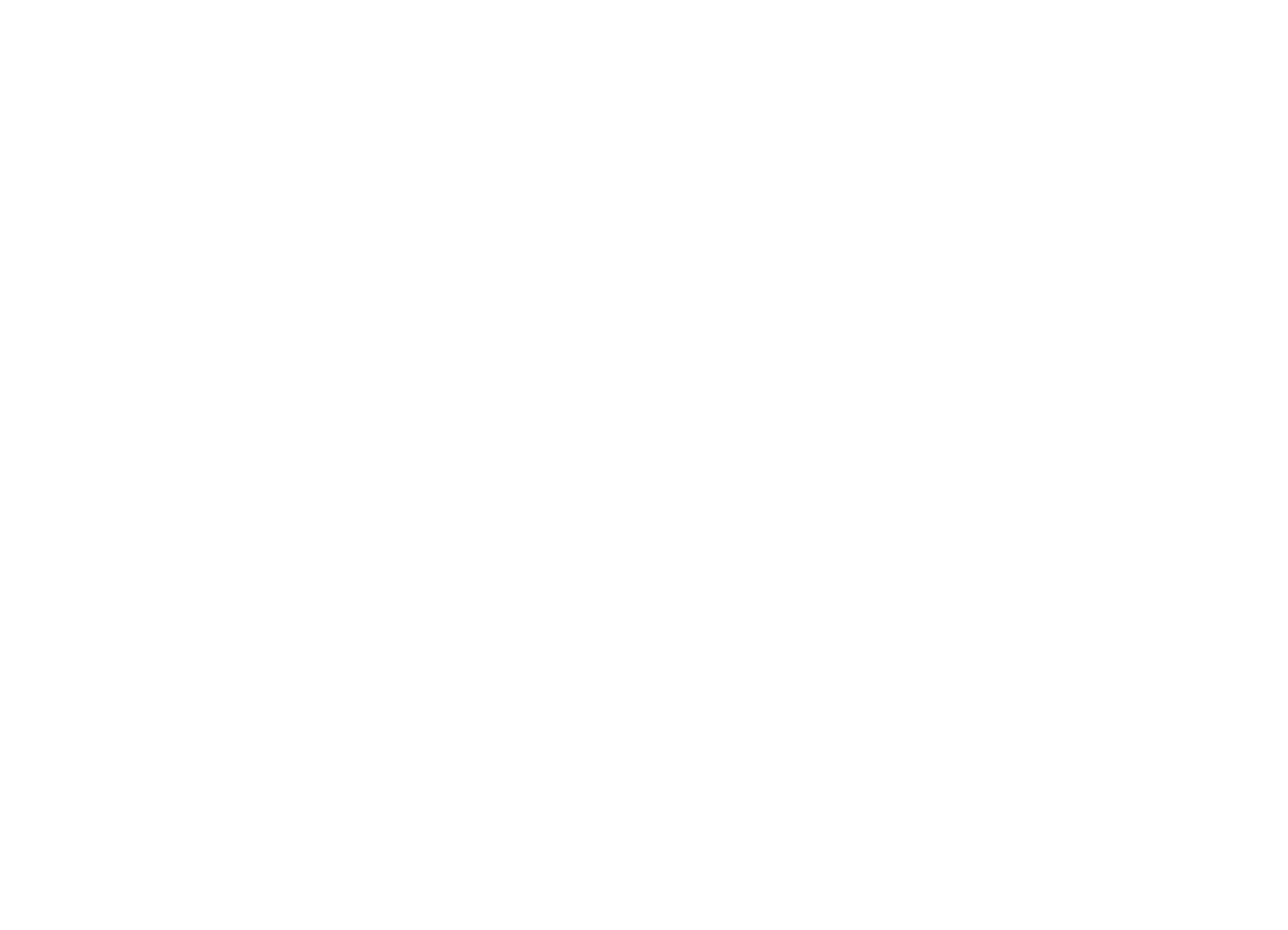

Glass is 100% recyclable and it should never be trash. In addition, increasing the amount of recycled glass in each batch of new glass causes significant reductions in energy used and emissions produced during the glass-making process.

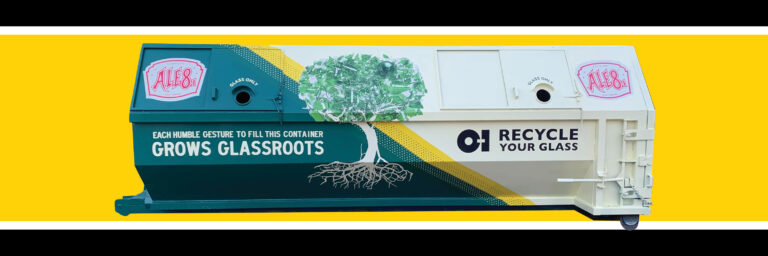

O-I is partnering with Ekored for the new hub. The new facility will leverage cullet recovery with Ekored’s PET chain in the northern coastal area of Colombia. The cullet hub, located in the same business center as the PET and scrap recycling centers, conveniently allows recycling suppliers to carry all three materials in the same truck.

“We know when it comes to sustainability, we need to join forces to achieve greater impact,” explains Monica Franco, O-I Sustainability Leader, Andean Country Group.

Colombia’s cullet supply falls into three general categories: readily accessible cullet close to the plants, inaccessible cullet due to its distance from the plants, and cullet in landfills, to which we do not have access. According to Franco, the PET recycling chain works well in the North Coast region, making the hub key to recovering the cullet available in the market but located far from our plants.

The mid-term goal is to bring in an additional 600 metric tonnes of recycled glass packaging per month; Franco anticipates it may happen by the end of 2022. The cullet hub and partnership with the Barranquilla area’s major PET recycling company exemplify O-I’s innovative approach to glass recycling. Globally, we are working with our customers, suppliers, municipalities, and partners to find solutions to create a strong circular economy that keeps more recycled glass packaging in the loop.