A glass recycling program with the power to positively impact the community has come to Warren County, Kentucky. The program caps a year of groundbreaking programs, strategic partnerships, and innovative technology as O-I advances glass recycling and transforms waste into opportunity in our North American and Latin American footprint.

The Warren County Parks and Recreation department, United Way of Southern Kentucky, and O-I Glass officially kicked off the area’s Glass4Good™ program in late November. Glass4Good incentivizes glass recycling by making regular charitable donations to non-profits in the community.

The program is strategically located to support the community near our new glass-making plant in Bowling Green, Kentucky. Ensuring that our plant communities can easily recycle glass bottles and jars is part of our corporate sustainability commitment.

“We are often asked about what continues to make Warren County such a great place to live, and this is a prime example – collaboration of partners across our community to benefit one another and the entirety of our community,” Warren County Deputy Judge-Executive Bryan Downing said in a news release.

This initiative aims to maximize the impact of every glass bottle by reinvesting in our communities. Residents and businesses drop off glass for recycling, which is then processed and reintroduced into O-I’s manufacturing stream to make new glass bottles and jars. By reducing landfill waste and creating a local supply chain of high-quality cullet, Glass4Good ensures that every recycled bottle helps build a more sustainable future.

“We know the recycling collected through the Glass4Good program will have a positive ecological impact, and then the byproduct of the recycled glass will help our community by creating funding to help United Way make a difference in our community,” said Debbie Hills, CEO of United Way of Southern Kentucky.

This initiative joins a growing network of Glass4Good programs across Virginia, Pennsylvania, and Colorado. Together, these locations collected 25% more glass in 2024 than the previous year, demonstrating the program’s success.

“Programs like Glass4Good are a testament to what’s possible when communities and industries work together to embrace recycling,” said Bob Hippert, Sustainability Strategy Leader at O-I. “By keeping glass in the manufacturing stream, we’re conserving natural resources, reducing emissions, and supporting local economies.”

Expanding Glass Recycling in Kentucky’s Bourbon Country

Glass4Good in Bowling Green isn’t the only new opportunity to recycle glass in Kentucky in 2024. This year, Workwell Industries launched the “RecycWELL” initiative in West Louisville, in collaboration with O-I and major distillers like Suntory Global Spirits, Diageo North America, and Pernod Ricard.

Strategically located in Bourbon Country, RecycWELL aims to provide essential glass recycling services and create job opportunities for the local community. The initiative focuses on managing end-of-life glass from local distilleries, restaurants, bars, and businesses, which is processed into cullet and recycled into new glass bottles at our plants.

By recycling glass locally, the region can maintain a sustainable supply of materials needed for glass packaging, helping distillers and manufacturers reduce carbon emissions and conserve natural resources.

“We are thrilled to be part of this collaborative initiative, investing in the future to bring jobs and improve glass recycling infrastructure in Kentucky,” said Gabriel Opoku-Asare, Director, ESG/Society of Diageo North America.

MOGRA: A Mobile Revolution in Glass Recycling

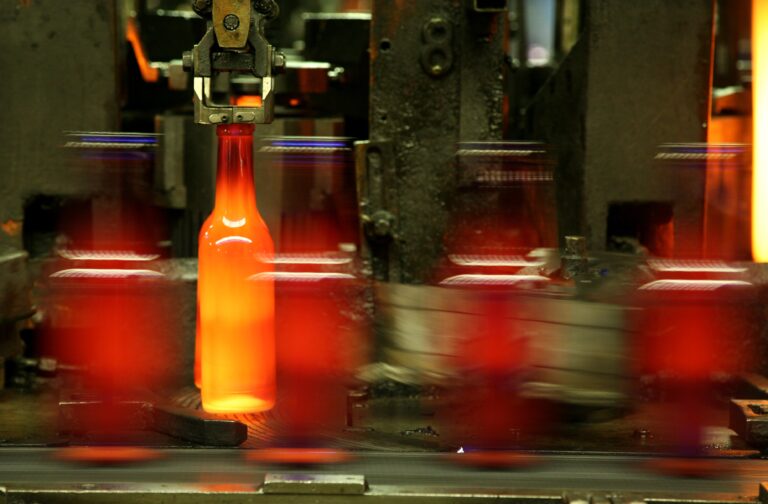

As community programs like Glass4Good grow, O-I is also breaking new ground with innovative technology designed to bring glass recycling to underserved areas. The Mobile Glass Recycling Asset (MOGRA) was a standout achievement in 2024, revolutionizing recycling with its modular, transportable system.

Launched at O-I’s Danville facility, MOGRA can process up to 6,000 metric tons of glass annually. It crushes glass to precise sizes and removes metallic content like caps and closures, producing furnace-ready cullet. Operators can transport MOGRA on a truck trailer, set it up in less than a day, and quickly turn glass waste into valuable raw material.

“MOGRA exemplifies the innovative spirit of O-I,” said Randy Burns, Chief Administrative and Sustainability Officer at O-I. “By solving logistical and infrastructure challenges, we’re enabling more communities and industries to recycle glass, reducing costs while creating furnace-ready cullet.”

Redefining Glass Recycling in Colorado

O-I has multiple projects in Colorado. We joined the “Don’t Trash Glass” program, a statewide initiative to address the state’s low glass recycling rate of 11%. By teaming up with bars, restaurants, and hospitality venues, the program collects glass, processes it locally, and turns it into new bottles at O-I’s Windsor facility or the Rocky Mountain Bottle Company.

“Glass is never trash,” Hippert emphasized. “Every bottle recycled represents a step toward conserving resources, creating jobs, and reducing the energy needed for glass production.”

This effort supports O-I’s global recycling goals, conserving nearly in 2024 through initiatives like Don’t Trash Glass. The emissions saved from capturing and keeping that glass in the manufacturing stream is equivalent to taking about 37,000 cars off the road for a year.

O-I is also partnering with Goodwill of Colorado to make glass recycling more accessible in Denver, Englewood, and Colorado Springs. Glass collected through this program is processed at O-I’s Glass to Glass facility in Broomfield and turned into new bottles in as little as 30 days.

“We are grateful for Goodwill of Colorado’s commitment to making glass recycling accessible to community residents,” said Danielle Brickner, Sustainability Collaboration Specialist at O-I. “Together, we’re driving waste reduction, conserving energy, and creating jobs.”

Transforming Glass Recycling in Latin America

O-I pursued programs and partnerships across Latin America to increase cullet. In México, O-I’s initiatives blended sustainability with social impact. At the Querétaro plant, the “Recycle to Help” program turned 90 tons of glass waste into critical support for the San Pablo Home, a care facility for individuals with disabilities. By transforming discarded bottles into essential resources, the program prevented waste from reaching landfills and demonstrated how sustainability can change lives. José Nieves, a program leader, reflected, “Every bottle we recycle brings hope and opportunity to those who need it most.”

Continuing its focus on innovation, O-I México partnered with SILICE to launch the first glass recycling hub in Chihuahua. This cutting-edge facility processes 300 tons of glass each month, reducing energy consumption and CO2 emissions while providing furnace-ready cullet for the Monterrey plant. Founders Paulina Rascón and Ashly Hinojos praised the project as a “turning point for México’s recycling movement,” driven by education and local engagement.

In Nuevo León, O-I México expanded its glass collection network, installing six strategically placed recycling containers that diverted over 7,000 glass bottles from landfills. Working alongside the Ministry of the Environment, these efforts fostered a culture of sustainability while reducing the need for raw materials.

In Brazil, the Volte Sempre Program in Arraial do Cabo, created in collaboration with Heineken, recycled over seven tons of glass in just one month. The program demonstrated how grassroots action can yield meaningful environmental change with strategically placed recycling bins and daily collections by the Costa do Sol Cooperative.

Advancing Glass Recycling

O-I’s community recycling programs and partnerships exemplify the company’s vision of a sustainable, circular economy. As O-I continues to innovate and invest in glass recycling, the company is steadfast in its goal to increase the global average of recycled content in its packaging to 50%. With initiatives like Glass4Good and MOGRA and collaborations with partners like Goodwill and distiller customers, O-I is building a more sustainable future.

“Glass is endlessly recyclable and integral to a circular economy,” Burns said. “Through innovation and collaboration, we’re ensuring that this remarkable material lives up to its full potential.”

O-I’s achievements in 2024 demonstrate that glass is the ideal packaging material to support a circular economy. By expanding these innovative programs, we’re continuing to reduce waste and showcase the transformative power of partnerships, cutting-edge technology, and community engagement in creating a brighter, more sustainable future.